more>>Industry Overview

more>>Link us

News

On December 4, at the rail welding factory of the track-laying base of the China Civil Engineering Construction Corporation (CCECC) UAE Branch, two 25-meter-long steel rails achieved seamless welding amidst sparks flying, marking the beginning of welding operations for the entire second phase of the UAE Railway project.

Currently, the track-laying base has commenced the welding task for the first batch of 8,000 tons and 12.5 kilometers of steel rails for the second phase of the UAE Railway. These steel rails will be transported to the construction frontline subsequently, laying the foundation for the construction plan of the second phase of the UAE Railway.

In the past, the roaring of steam locomotives and the "clanging" sound of railways accompanied many passengers on their long journeys. Nowadays, steam locomotives have been replaced by diesel and electric locomotives, and gradually, the "clanging" sound has faded away.

Old tracks were made by welding 25-meter-long steel rails into 100-meter-long sections, and a 1-centimeter gap was left between each rail during laying to facilitate transportation and to accommodate thermal expansion and contraction. This is why trains produced a rhythmic "clang, clang" sound when running. These gaps limited train speeds and caused significant wear and tear on rail heads and wheels.

Seamless tracks, however, eliminate these gaps. They weld each 25-meter-long steel rail into 400-meter-long sections in the workshop, which are then transported to the laying site and welded together to form a seamless line. The "clang, clang" sound has been replaced by a "swish, swish" sound.

The second phase of the UAE Railway project is located in the United Arab Emirates. The line starts from the Emirate of Abu Dhabi and stretches northeast across five emirates: Dubai, Sharjah, Ras Al Khaimah, Fujairah, and ends at the Port of Fujairah, with a total length of 449.78 kilometers. Half of the UAE is sea and half is desert, with a tropical desert climate. Half of the year experiences temperatures above 40 degrees Celsius, and there is a large diurnal temperature variation, placing high demands on the quality of steel rails.

To adapt to the climatic conditions of the UAE Railway, the track-laying base controls product quality from the source, adhering to the principle of "selecting the best from the best." It conducts secondary screening of qualified raw material rails to ensure optimal parameters such as rail profile, quality uniformity, and metal internal crystal grain size. The physical properties of the welded finished rails are as close as possible to the design theoretical values, reducing the deformation of the rails in environments with large temperature differences and effectively lowering the difficulty of stress relief during subsequent laying construction.

A complete seamless long rail reaches a length of 400 meters, equivalent to the circumference of the inner lane of an IAAF stadium track. Unlike ordinary welding techniques, welding 16 pieces of 25-meter-long steel rails into a 400-meter-long rail requires seven processes: appearance and size inspection, rust removal, coarse grinding after welding, water cooling, precision straightening, precision grinding, and ultrasonic flaw detection of the weld. The straightness tolerance between the two welded steel rails cannot exceed 0.3 millimeters, equivalent to the thickness of four human hairs.

"The key to good rail welding lies in the strength of the weld joint," said Shao Hualei, the chief engineer of the track-laying base. The track-laying base focuses on optimizing the heat treatment process of weld joints, using infrared high-frequency induction heat treatment and water cooling technology to improve the hardness, strength, and wear resistance of the welded areas. This significantly enhances the tolerance of steel rails to the climatic conditions of the laid sections, extends the service life of steel rails, and provides a reliable guarantee for the safe, stable, and high-speed operation of trains in the later stages.

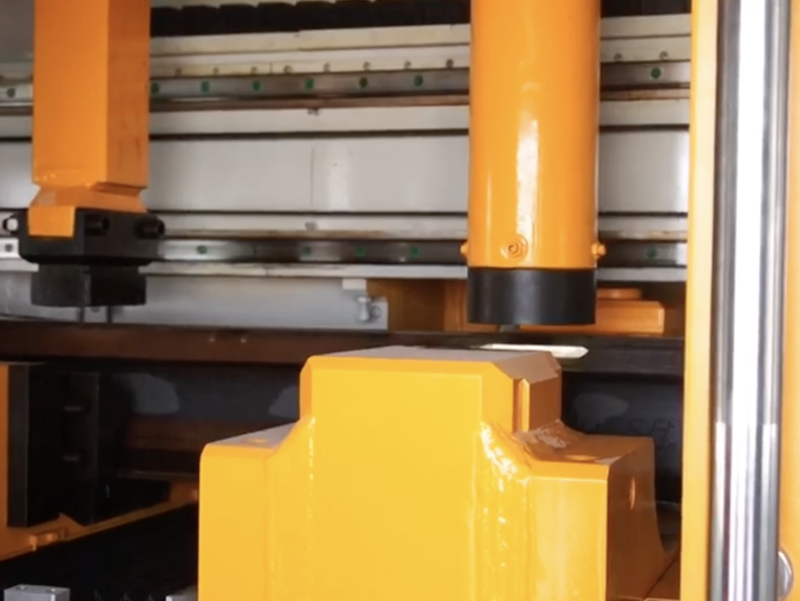

Rail welding

Coarse grinding after rail welding

Straightening after rail welding

Ultrasonic flaw detection of rails

To ensure production progress, the track-laying base plans to weld 90 joints per shift, allocating the welding workload of steel rails reasonably. It is estimated that approximately 50,000 weld joints will be completed along the entire line by January 2022, timely meeting the engineering demands and safeguarding the track-laying construction of the project.

Source: CCECC Middle East